Why PMC?

- Start date

- Why PMC?

Advantages of PMC Attachment

PMC Attachment is one of Northern Europe’s leading manufacturers of integrated fork positioners , 1-25 tons. PMC Attachment offers:

- Integrated fork positioners from 1-25 tons

- Reliable and robust products with a long lifespan

- 30 years of experience, great customer focus and high service level

- Customer and special adaptations to your unique needs

- Short lead times and reliable deliveries

- ISO certified operations according to 9001, 14001, 3834-2 and 4406

- Hydraulic and electromechanical solutions to customer needs

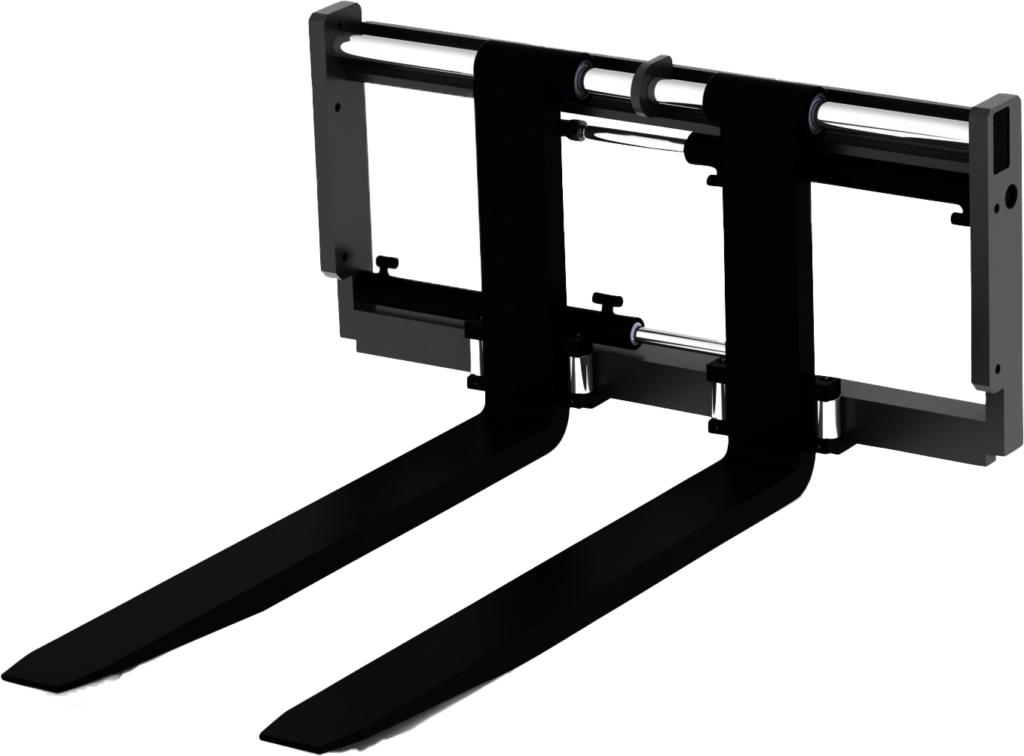

Advantages of the PMC Attachments Fork positioner

PMC Attachments fork positioner are designed for maximum – opening area – visibility for the best possible material handling. The big advantage of the fork positioner with side shift is that the driver can control the fork spreading and side shift from the cab without leaving it. With a fork positioner from PMC Attachment you get:

- Increased safety and better working environment

- Lower costs and higher productivity

- Saves time and makes the truck more flexible

- Less risk of damaged goods

- No need for the driver to jump in and out

Advantages of PMC Attachments E-Clamp (electric stabilizer)

PMC Attachment’s unique and compact electric E-clamp for cargo stabilization. The E-clamp is equipped with a pressure plate that holds the goods in place without touching the corners. The e-clamp can be controlled via a display in the cab and has an integrated PLC system that includes the movement, speed and pressing force are adapted to customer requirements, which means:

- Less risk of damaged and lost goods

- Increased safety and better working environment

- Takes up little space and maintains transparency

- Faster and more stable freight handling

We are happy to help you

PMC Attachment stands for high quality, delivery reliability and unique innovative solutions that take cargo handling to a new level.